Beckman Allegra 21R Centrifuge Repair

Problem Encountered

The Beckman Allegra 21R centrifuge was not reaching an adequate speed: the rotor started spinning, but did not exceed 100-200 RPM. No errors were displayed, making it difficult to diagnose the problem. This type of defect is related to a motor speed sensor that does not send correct data to the circuit board, preventing the rotor speed from being controlled.

Solution

The cause of this malfunction is the magnetic cylinder (similar to a ball bearing) at the bottom of the motor shaft, which communicates the motor speed to the control board via a magnetic field sensor. This magnet can detach from the motor shaft or remain attached but rotate freely, preventing the sensor from properly detecting the speed. Here are the steps to fix the problem:

- Turn off the centrifuge and disconnect it from the power supply.

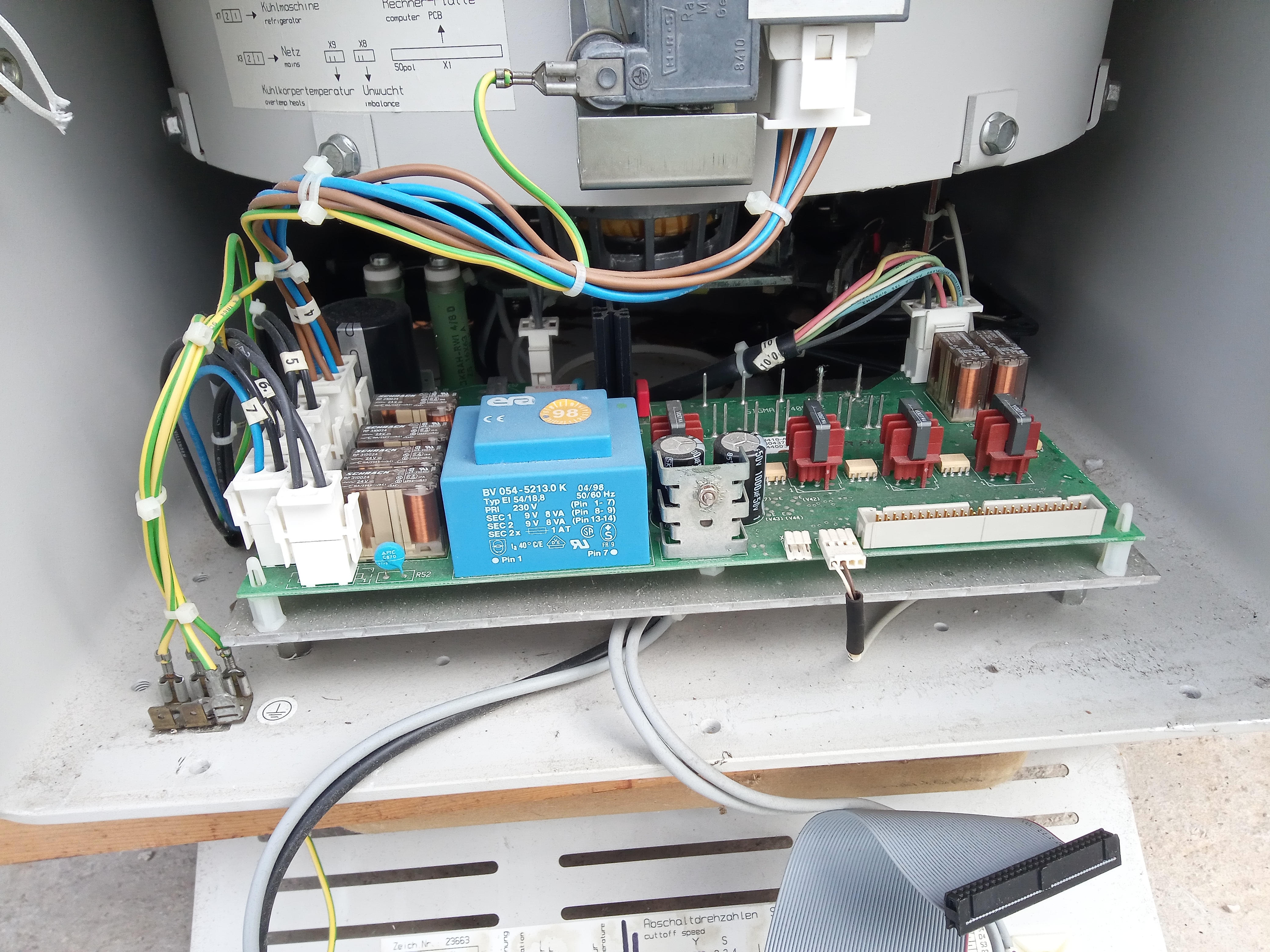

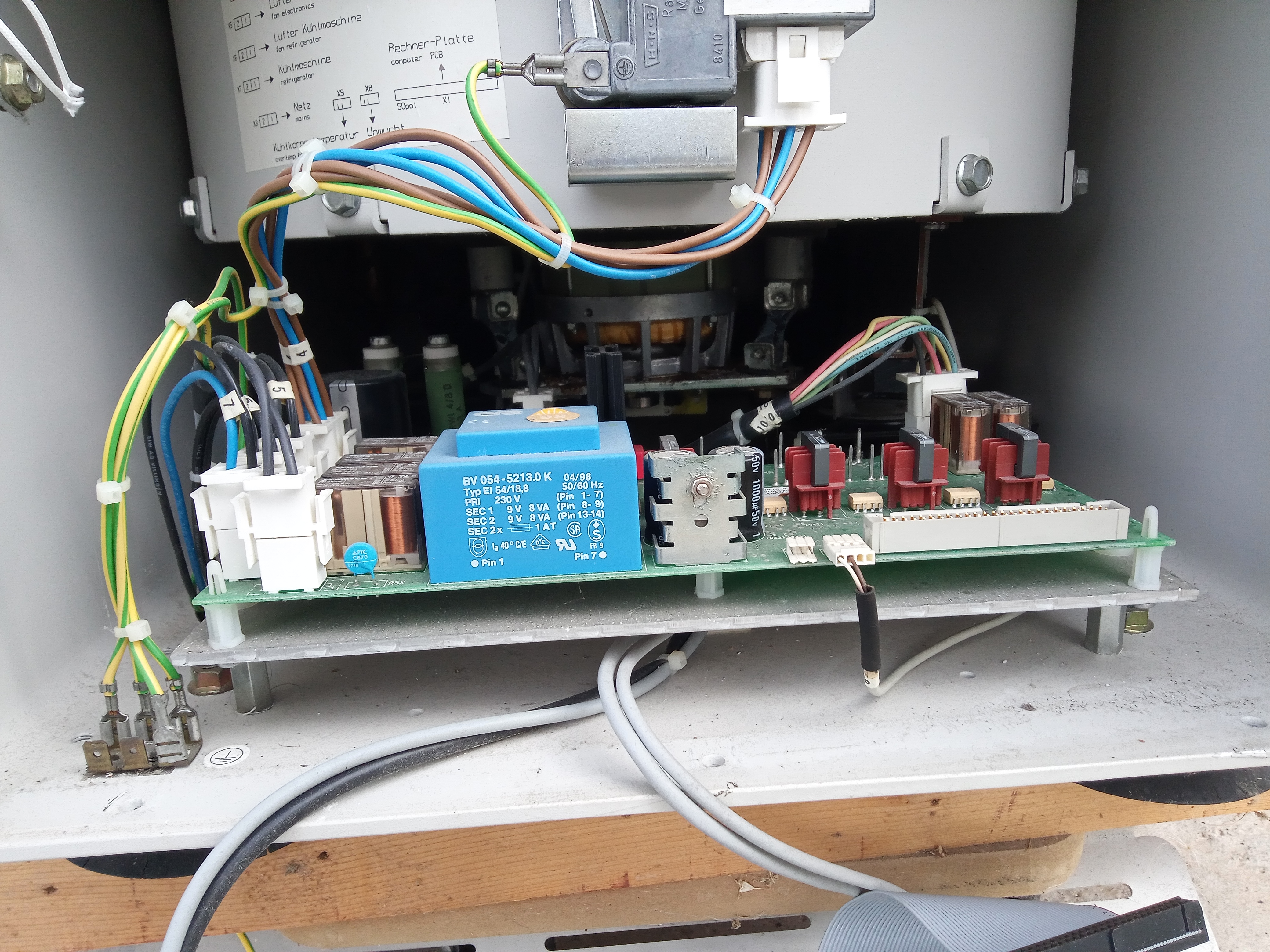

- Remove the front panel by unscrewing the 5 screws holding it in place. This will give you access to the inside of the machine.

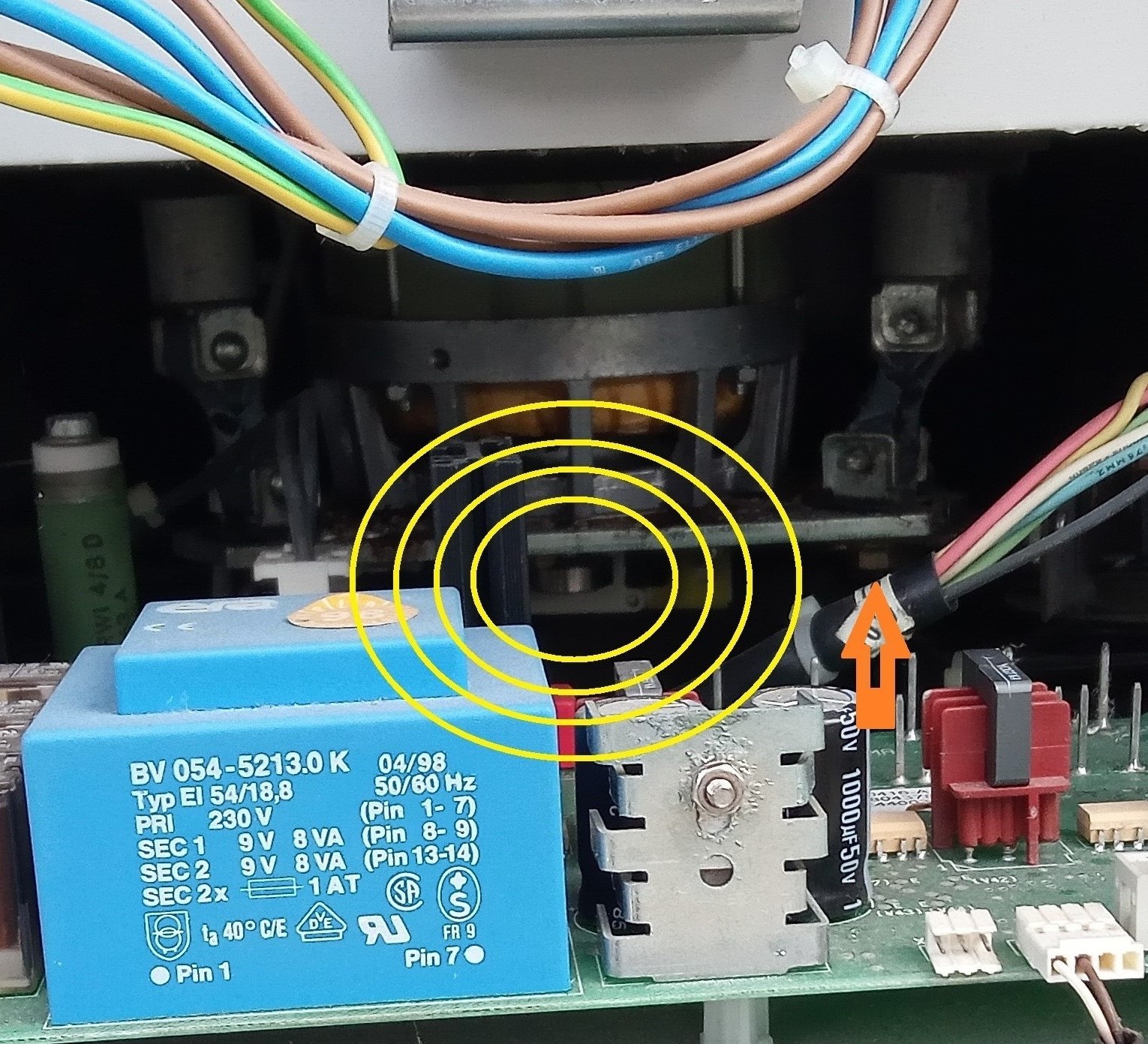

- Examine the bottom of the motor shaft: by looking through the open panel, you can see the bottom of the motor where the small magnetic cylinder is located.

- Inspect the magnet: the magnetic cylinder may have detached or be spinning freely on the motor shaft. This magnet is crucial for the motor's speed sensor to function.

- Clean the magnet and shaft: use a solvent to remove dust, oil, and other debris from both the magnet and the motor shaft. This ensures the magnet adheres properly.

- Secure the magnet: apply strong adhesive to the magnet and reattach it to the shaft.

- At this point, it is advisable to clean the inside of the centrifuge by blowing air. It may also help to disconnect and reconnect each electrical connector to ensure electrical contacts are secure. In the previous image, an arrow points to a nut I found loose, so it's recommended to check the fastening of nuts subjected to stress and vibration. Reassemble the front panel and test the centrifuge.

Problem Encountered

In another Beckman Allegra 21R centrifuge, error 28 appeared on startup, and sometimes the "notA1" error also appeared on the display. Despite attempts to reset using the control panel (pressing the following key combinations: press the up arrow once, press Enter twice, press Enter a third time and hold until the menu appears on the display, scroll through the menu with the arrows to select the reset option), the error kept reappearing. However, the problem turned out to be the same as the magnet issue we just described.

Additional Steps to Resolve Error 28

- Follow all the procedures listed previously to check and secure the magnet. Disconnect and reconnect all electrical connectors (sometimes, false contacts due to oxidation of the pins are the cause of problems).

- In my case, the error persisted, even after resetting from the panel again. I solved the problem by leaving the centrifuge on for about half an hour. Perhaps this allows the system to "self-repair." I then performed the reset procedure again and this time, the error did not appear. I immediately set the rotor type and everything worked again.